Learn to choose the right steel pipe size for your project. Our guide covers 10, 12, & 24-inch pipes and more, offering key insights for any application.

Introduction

Steel pipes play an indispensable role in various industries of modern society. Whether constructing skyscrapers, establishing modern transportation systems, or playing a key role in energy transportation and industrial manufacturing, steel pipes, with their unique strength, durability, and flexibility, have become the lifeblood of modern civilization's development. They support the physical structure of our world and are a crucial driving force behind economic growth and human progress. From the skyscrapers of the construction industry to the precision machinery of manufacturing, from the global network of energy transportation to the plumbing systems of every household, the application of steel pipes spans nearly every corner of modern society.

Steel pipes possess a variety of hard indicators, such as physical properties, mechanical performance, and chemical composition, all of which determine their performance in extreme conditions like humidity, corrosion, and high temperatures. Size is also an important product parameter of steel pipes. We find that there are many sizes of steel pipes available on the market, including standard stock sizes available on local steel market websites and platforms; there are also customized sizes, which are generally offered by B2B steel companies as a part of their product services. However, regardless of which size is chosen, it is essential first to understand the size requirements of your project and product, and how to measure whether the steel pipes provided by suppliers meet these specifications. Therefore, this article aims to provide necessary advice for choosing the size of steel pipes for your needs.

Let’s start with the composition of steel pipe sizes

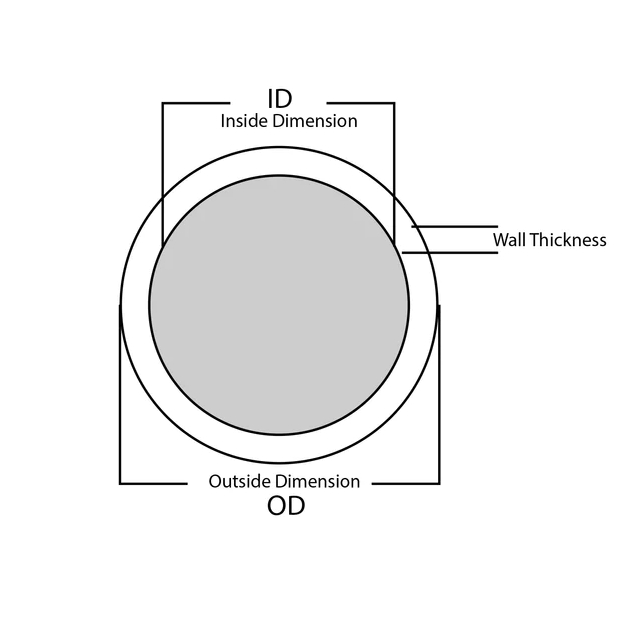

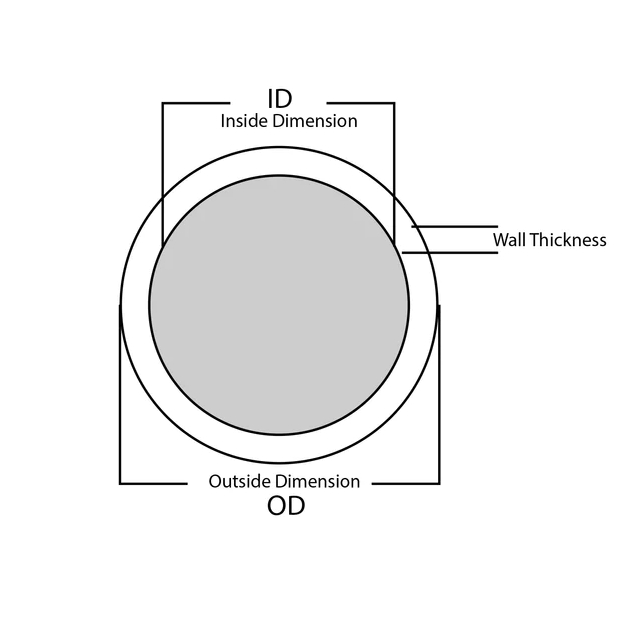

When we start discussing steel pipe dimensions, we mainly focus on three core indicators: inner diameter, outer diameter, wall thickness, and length. These specific dimensional attributes collectively constitute the physical form of a steel pipe. Let's elaborate on these key parameters.

Diameter

Outer Diameter (OD): The outer diameter is the measurement of the steel pipe's outermost linear span, crucial for pipeline connection and installation. The outer diameter can be measured directly using calipers or measuring tools along the pipe's outer edge. In specification documents, the outer diameter often serves as one of the main bases for classifying steel pipes.

Inner Diameter (ID): The inner diameter refers to the steel pipe's internal space diameter size, directly related to the fluid's passing capacity. The size of the inner diameter is determined by the outer diameter minus twice the wall thickness.

Wall Thickness

Wall Thickness(WT): The wall thickness refers to the thickness of the pipe wall. It is one of the key parameters for a steel pipe to meet application requirements (such as pressure rating, strength, etc.). Too thin a wall thickness may not withstand higher working pressures, while too thick a wall thickness can increase costs and weight. The wall thickness of a steel pipe is usually measured using specialized tools like ultrasonic thickness gauges to ensure accuracy.

Length

Fixed Length: Fixed-length steel pipes are pre-cut to standard lengths to meet the needs of specific projects or applications. This type of steel pipe facilitates standardized production and bulk purchasing.

Non-Fixed Length: Non-fixed length steel pipes are customized to the length based on specific customer needs. This offers flexibility for special projects or custom installations but may increase the complexity and cost of production and processing.

Having understood the basic dimensional parameters of steel pipes, let's first acquaint ourselves with some standard sizes. These standard sizes generally originate from various countries, regions, or corresponding industry organizations, providing size references. These standards explicitly define the dimensions that steel pipes should refer to in specific applications. Many suppliers also produce and store standard products according to these specified sizes. The following are some relatively common industry standards.

International Standards

ISO (International Organization for Standardization): ISO standards are transnational, aiming to facilitate global trade and communication. For steel pipes, ISO standards comprehensively cover dimensions, materials, performance requirements, and testing methods. For example, ISO 3183 specifies the dimensions and materials for steel pipes used in the oil and gas industry North American Standards

North American Standards

ASTM (American Society for Testing and Materials): ASTM standards are particularly important in North America, providing detailed specifications for dimensions and materials of steel pipes used in construction, mechanical, chemical, and other industries. For instance, ASTM A106 specifies the standard for seamless carbon steel pipes for high-temperature service. API (American Petroleum Institute): For the oil and gas industry, API standards are especially crucial. The API 5L standard specifies the dimensions, strength, and technical conditions for steel pipes used to transport gas, water, and oil.

API (American Petroleum Institute): For the oil and gas industry, API standards are especially crucial. The API 5L standard specifies the dimensions, strength, and technical conditions for steel pipes used to transport gas, water, and oil. European StandardsEN (European Standard): European standards facilitate trade within the EU by providing uniform technical specifications. In EN standards, for example, EN 10210 specifies the dimensions and technical requirements for seamless and welded steel pipes for structural purposes.

European StandardsEN (European Standard): European standards facilitate trade within the EU by providing uniform technical specifications. In EN standards, for example, EN 10210 specifies the dimensions and technical requirements for seamless and welded steel pipes for structural purposes. Asian StandardsJIS (Japanese Industrial Standards): JIS standards are widely applied in Japan and other Asian regions, covering the dimensions, materials, and usage conditions of steel pipes. For instance, JIS G3452 specifies the dimensions and technical conditions for carbon steel pipes for general use.

Asian StandardsJIS (Japanese Industrial Standards): JIS standards are widely applied in Japan and other Asian regions, covering the dimensions, materials, and usage conditions of steel pipes. For instance, JIS G3452 specifies the dimensions and technical conditions for carbon steel pipes for general use. GB (China National Standard): China's GB standards cover a wide range of steel pipe types and uses, providing specifications for manufacturing and construction in China. For example, GB/T 3091 specifies the dimensions and technical conditions for welded steel pipes used for low-pressure fluid transport.

GB (China National Standard): China's GB standards cover a wide range of steel pipe types and uses, providing specifications for manufacturing and construction in China. For example, GB/T 3091 specifies the dimensions and technical conditions for welded steel pipes used for low-pressure fluid transport.

Following the discussion of various international and regional standards, it's important to note that these standards employ different units of measurement, with some using inches and others millimeters. This necessitates careful reading of the standard documents and attention to detail in their various specifications. Next, we will present some common steel pipe sizes and introduce their applications, highlighting how these dimensions serve specific purposes across diverse industries. This step is crucial for understanding the practical implications of steel pipe standards and ensuring the selection of appropriate specifications for your project needs.

How to Choose the Right Steel Pipe Size for Your Project

Selecting the appropriate steel pipe size is a critical decision that can significantly impact the efficiency, cost-effectiveness, and longevity of your project. To navigate through this crucial choice, it's essential to follow a structured decision-making framework that considers several key factors.

1. Assess Project Requirements:

Begin by thoroughly understanding your project's specific needs. What is the purpose of the steel pipe in your project? Whether it's for transporting water, gas, oil, or for structural purposes, the nature of its use will heavily influence the size and type of pipe required.

2. Flow Volume and Capacity:

Evaluate the volume of material (liquid, gas, or solid) that needs to be transported through the pipe. Higher volumes necessitate larger diameters to ensure smooth flow and prevent bottlenecks or overpressurization.

3. Pressure and Temperature Conditions:

Consider the operating pressure and temperature conditions the pipe will be exposed to. High-pressure applications demand pipes with greater wall thickness (reflected in the pipe's schedule) to maintain integrity and safety.

4. Installation Environment:

The environmental conditions where the pipe will be installed play a crucial role. External factors, such as corrosive environments or extreme temperatures, may require specific materials or additional protective coatings.

5. Cost Considerations:

While larger pipes offer increased capacity, they also come with higher material and transportation costs. Balance the initial investment against the expected efficiency gains and operational savings to determine the most cost-effective option.

6. Availability and Lead Times:

Availability of specific pipe sizes and materials can vary, potentially impacting project timelines. Early consultation with suppliers can help identify any potential availability issues and allow for timely procurement.

7. Installation and Maintenance:

Ease of installation and future maintenance requirements are vital considerations. Ensure that the chosen pipe size is compatible with existing systems or infrastructure and consider access for maintenance and inspection activities.

8. Projected Lifespan and Durability:

Finally, consider the expected lifespan of the pipe and its durability under operational conditions. Investing in higher quality materials or specific pipe sizes can result in longer service life and reduced need for replacements.

Decision Framework Summary:

By methodically assessing these factors, project managers and engineers can develop a comprehensive understanding of their project's unique requirements. This approach enables informed decision-making that aligns with both immediate project needs and long-term operational goals. Remember, consulting with industry experts and suppliers can also provide valuable insights and recommendations tailored to your specific project context.

HYT - Your Trusted Metal Product Source

Jiangsu HYT International Trading Co., Ltd. stands as a fully-owned subsidiary of Wuxi Lusheng Special Steel Co., Ltd. Our foundation is built on a strong commitment to extending our reach beyond domestic borders, focusing on international sales and market exploration for a vast array of steel product. We are metal experts and have been providing quality customer service and products since 2015.

We stock a wide range of shapes including: bars, tubes, sheets, plates and more. And we can cut metal to your exact specifications.Contact us for more information regarding premium steel pipe at +86-18921111366 or [email protected] and we will gladly discuss the specific requirements of your next project. HYT is your premium resource for various premium steel pipe

North American Standards

North American Standards API (American Petroleum Institute): For the oil and gas industry, API standards are especially crucial. The API 5L standard specifies the dimensions, strength, and technical conditions for steel pipes used to transport gas, water, and oil.

API (American Petroleum Institute): For the oil and gas industry, API standards are especially crucial. The API 5L standard specifies the dimensions, strength, and technical conditions for steel pipes used to transport gas, water, and oil. European Standards

European Standards Asian Standards

Asian Standards GB (China National Standard): China's GB standards cover a wide range of steel pipe types and uses, providing specifications for manufacturing and construction in China. For example, GB/T 3091 specifies the dimensions and technical conditions for welded steel pipes used for low-pressure fluid transport.

GB (China National Standard): China's GB standards cover a wide range of steel pipe types and uses, providing specifications for manufacturing and construction in China. For example, GB/T 3091 specifies the dimensions and technical conditions for welded steel pipes used for low-pressure fluid transport.